|

Monday, December 14, 2020

Since April 2018, Shelving Inc. has been working with Webasto, a global innovative systems partner to almost all automobile manufacturers. After winning a contract for the 2021 Ford Bronco, Webasto recognized the need for more space to fulfill the task at hand. Webasto then purchased land, began developing an 880,000 sq. ft. facility with a $90 million renovation, and turned to Shelving Inc. to develop the critical racking system.

With a building of this size, our team had to make careful, thorough plans. After developing a layout, which needed to be approved by Ford and its 52 board members, we devised a plan to help Webasto optimize their new warehouse. With deadlines to meet in order to create a functional space, we initially set up a certain amount of racking to store certain products.

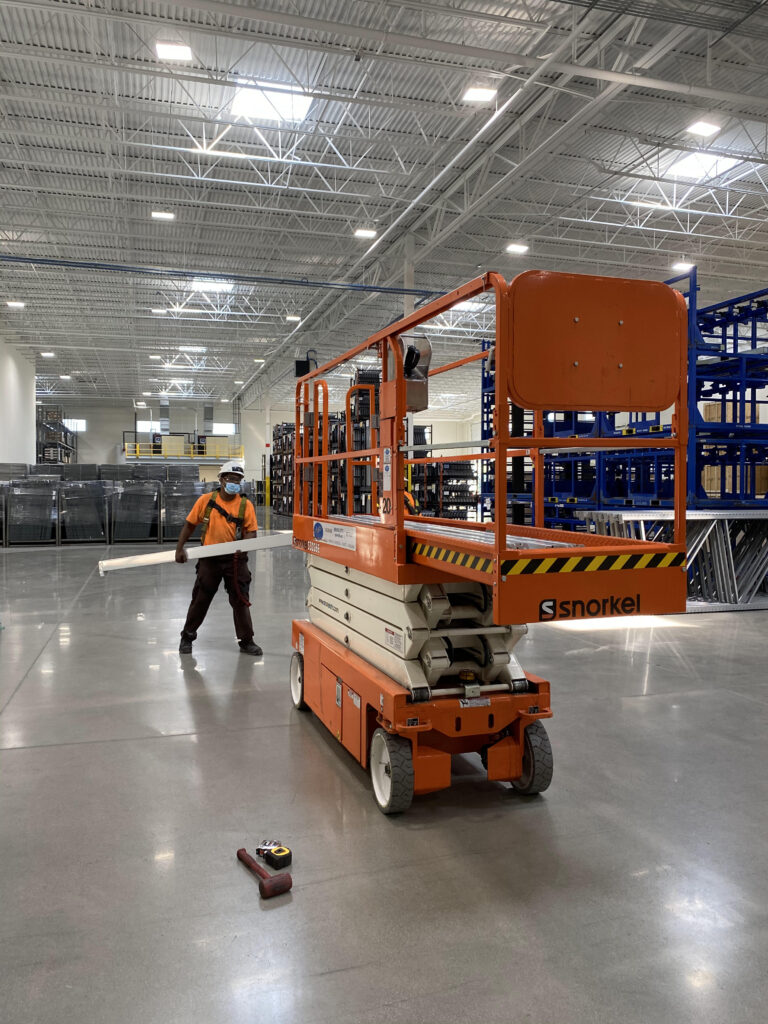

A Shelving Inc. crew member loads materials during installation.

One section of racking being installed.

We then gradually finished outfitting the rest of the space. To maximize the vertical space of their 30-foot ceilings, we installed pallet racking reaching 26 feet, allowing them to store full crates for the roofs of the Bronco all the way to the ceiling. Our team was able to use custom color powder coats to meet the corporate color codes.

Post protectors and aisle guards.

Post protectors

All posts have post protectors and aisle guards. We also added safety labels for capacity, as well as signage for each dock and aisle to ensure staff knew which product is where. We strategically configured the aisles to meet their specific needs. One side has a wide aisle for high-low picking, and the other side has a narrow aisle for tugger picking. This layout is more efficient than standard back-to-back aisles as it utilizes both sides of the rack

For additional safety, our team chose to add 20-foot wire mesh partitions to the racking to avoid items falling into the aisle or on drivers.

Wire mesh partitions we added to the racking.

In addition to these new configurations, Shelving Inc. met all the OSHA safety requirements, including adding safety labels for beam levels, and more signage for each dock and aisle. We maintained a steady pace the duration of the project – pausing the installation a few times to allow other parties in the project to catch up.

The final racking in place.

The new facility will now allow Webasto to produce 70,000 broncos each year and hold 1,848 pallet/crate spaces, increasing space warehouse efficiency by 75 percent. We are thrilled to be a part of this massive renovation, and look forward to the continued growth of our partnership with Webasto in their other facilities located in Rochester, Plymouth and Detroit. |